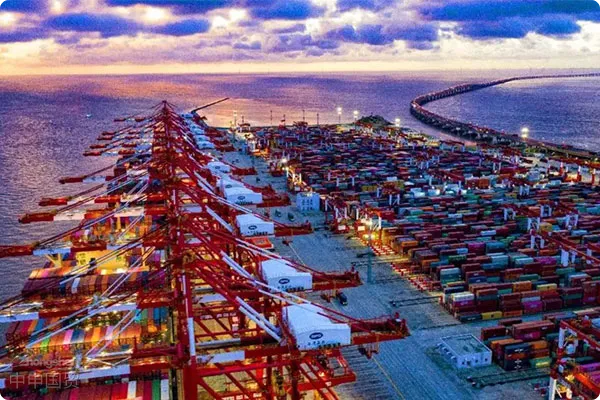

- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

Industry status and import pain points

In 2023, the total value of imported equipment in the printing and packaging industry exceeded $1.8 billion, with plate-making equipment accounting for 32%. However, customs data shows that the import declaration error rate for this category has remained at 12-15% over the past three years, mainly concentrated in commodity classification disputes, technical parameter misreporting,It is recommended to verify through the following methods:Three major areas of deficiency identified

Four core aspects of customs clearance practices

I. Accurate commodity classification positioning

- Classification differences between laser plate-making machines and CTP equipment

- 8442.3010 (Automatic flatbed plate-making machines)

- 8443.5920 (Digital direct plate-making equipment)

- Declaration principle for functional module separation

- Separate declaration of imaging units and mechanical transmission systems

- Independent classification of software control systems

II. Compliance strategies for document management

- Special documents required for submission

- Filing of Chinese language instructions for equipment operation interface

- Electromagnetic compatibility test report

- Common declaration error cases

- A company was required to pay 280,000 yuan in back taxes due to omission of automatic plate-making system declaration

- Late payment fees incurred due to using outdated version of certificate of origin

Risk prevention and cost control

III. Duty-paid value calculation techniques

- Key points for royalty fee declaration

- Allocation of specialized equipment software upgrade service fees

- Declaration boundaries for patent technology transfer fees

- Transportation Surcharge Handling Specifications

- Special Tool Transportation Costs for Equipment Commissioning (Itemized)

- Temporary Reinforcement Cost Calculation for Oversized Equipment

IV. Logistics Solution Optimization Path

- Special Transportation Requirements for Precision Equipment

- Shockproof Level Certification Document Preparation

- Temperature-Controlled Container Usage Filing

- Customs Clearance Efficiency Comparison Cases

- Shanghai Port Saves 7 Working Days by Adopting Advanced Declaration Mode

- Equipment Detention at Guangzhou Airport Due to Incorrect Customs Supervision Method Selection

Practical Case Studies

When a printing group imported CTP equipment worth 1.2 million euros, incorrect classification occurred due to failure to properly separate and declare the automatic plate feeding system. After professional agency intervention:

- Reassessed HS code 8443.5920

- Submitted supplementary documentation on equipment functional modules

- Applied for advance classification ruling procedure

Ultimately achieved compliant customs clearance with 96,000 yuan tax savings and avoided administrative penalty risks. This case demonstrates the importance of technical parameter verification and advance classification procedures.

Selecting professional agencies withequipment. For example, Indonesia has the SNI certification, Thailand has the TISI certification, and the Philippines has the BPS certification. It is necessary to confirm in advance the equipment voltage (such as 380V/50Hz in Thailand), the compatibility of the CE certification, and the proof of environmentally friendly materials.mechanical/electrical qualifications can effectively mitigate risks like classification disputes, documentation flaws, and logistics delays. Importers should prioritize three key agency capabilities: Customs AEO certification, historical performance in mechanical/electrical product imports, and localized customs clearance network coverage.

Related Recommendations

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912